Tube container for barrel cleaning rods and antenna

This post was going to be about hull texture and Zimmerit, but the application of this coating requires knowing where the various brackets and clamps will be located. To do this I'll have to finish most of the photo etch first to ensure their positioning is correct.

So...

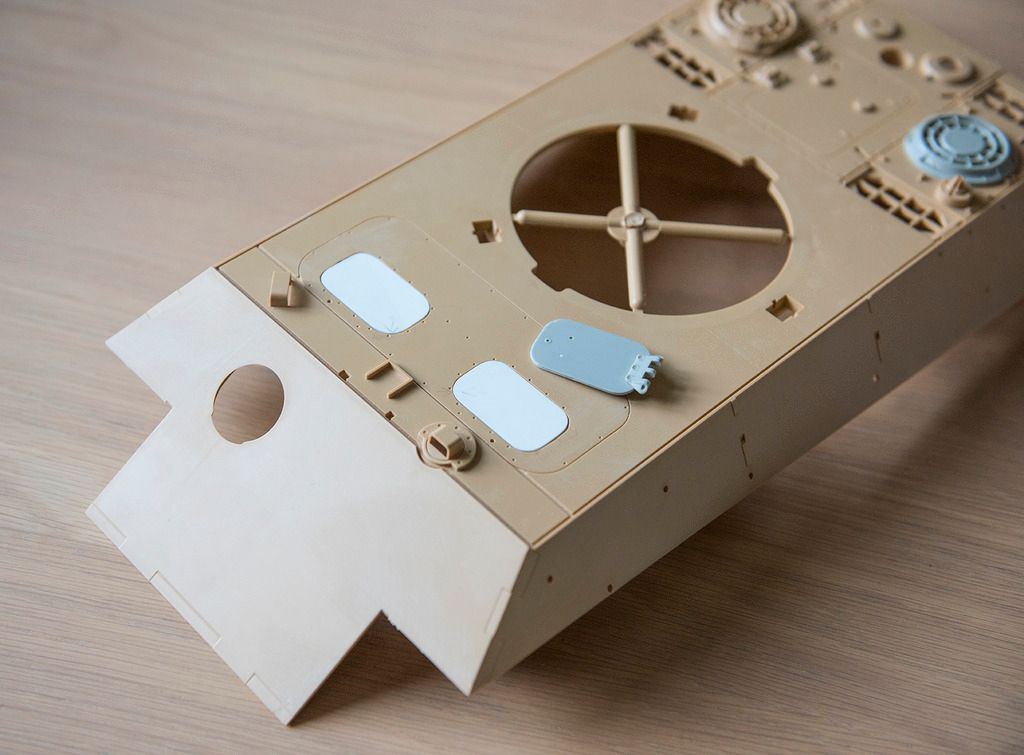

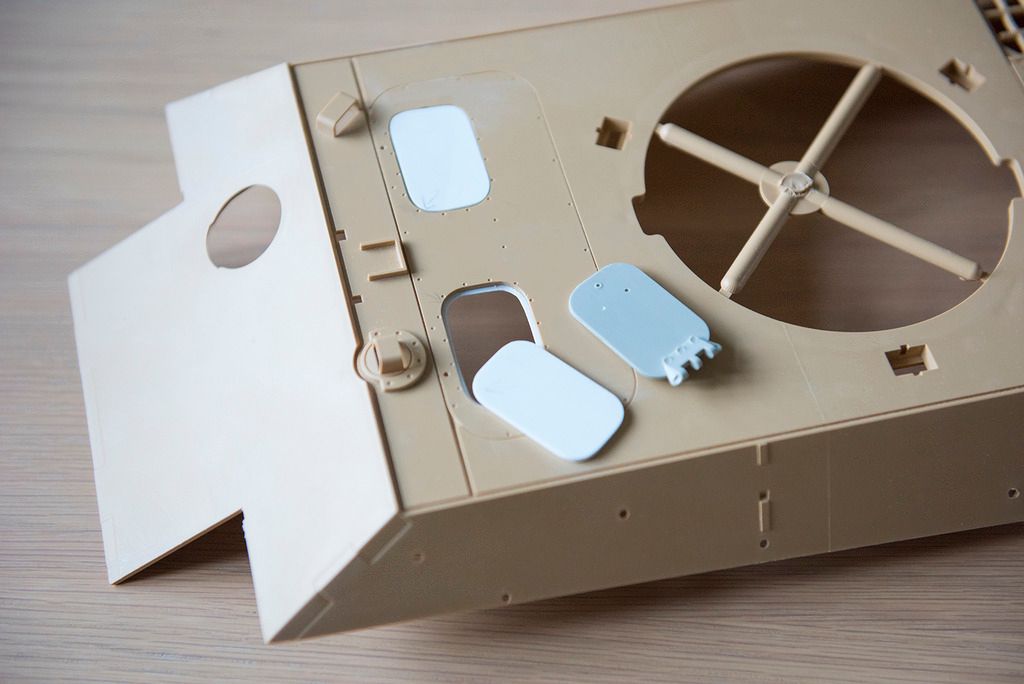

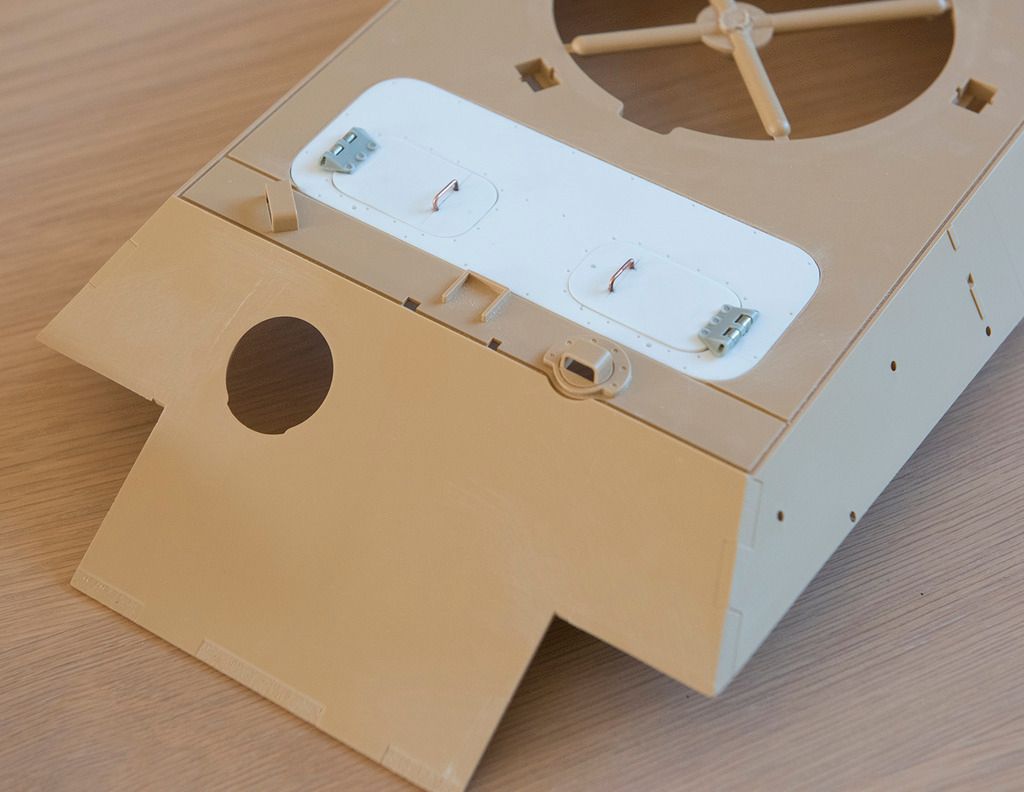

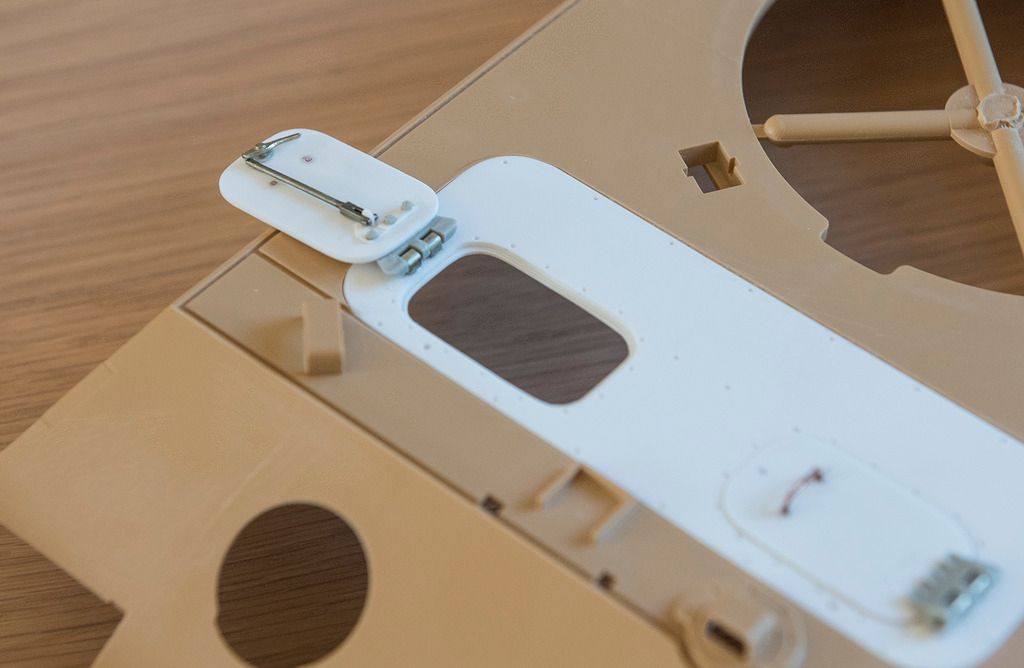

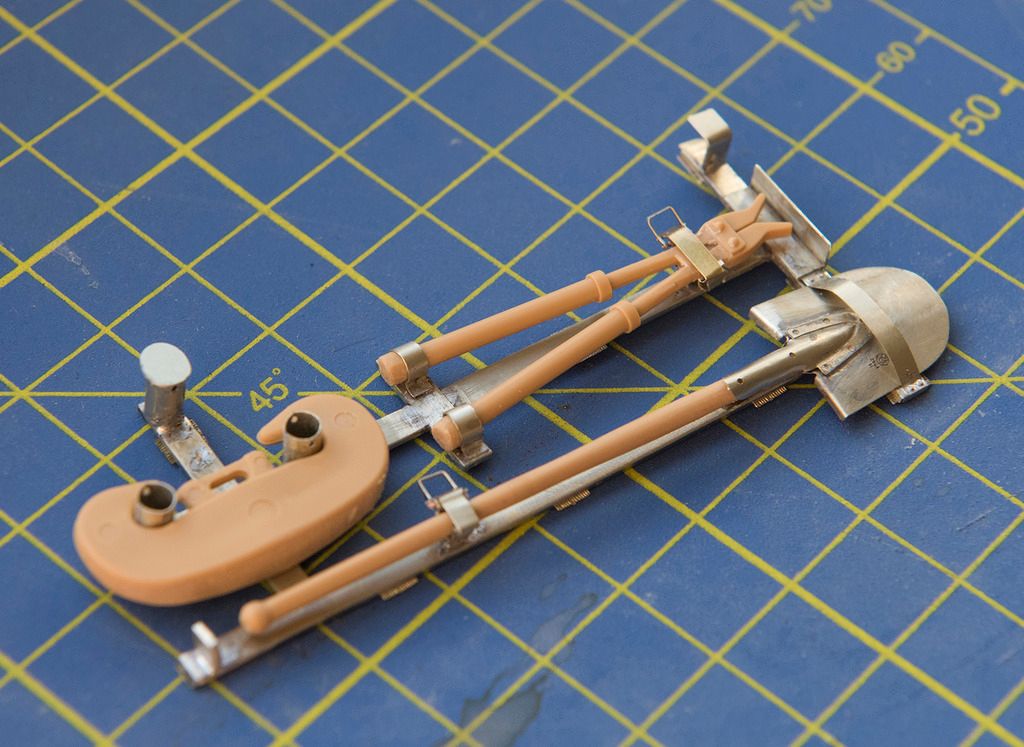

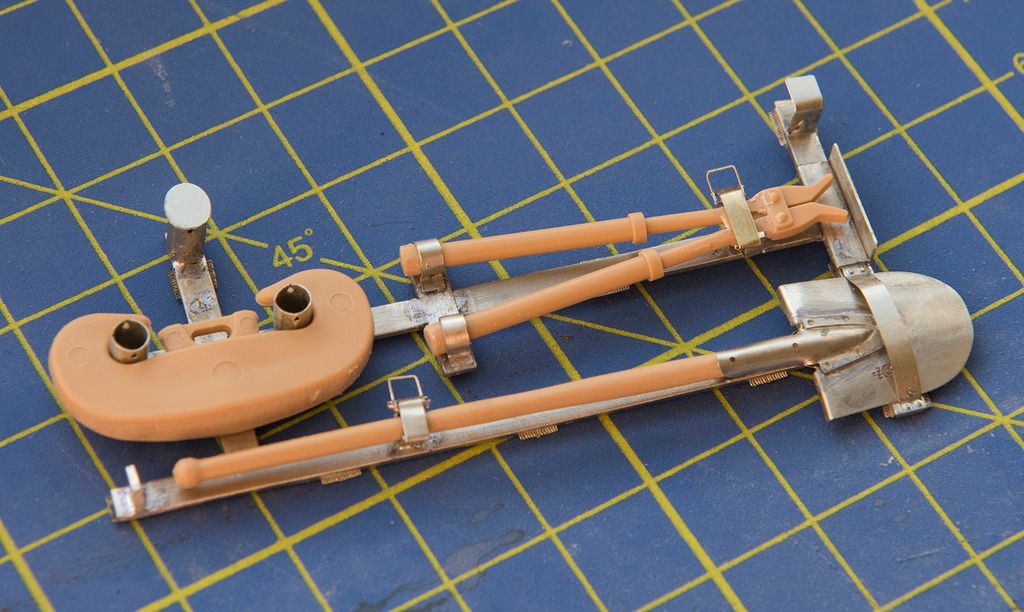

Today I finished the tube container found on the left hand hull side of most Panthers (crews of certain units moved theirs to the back of the rear deck). This tube was used to house the barrel cleaning rods and the antenna.

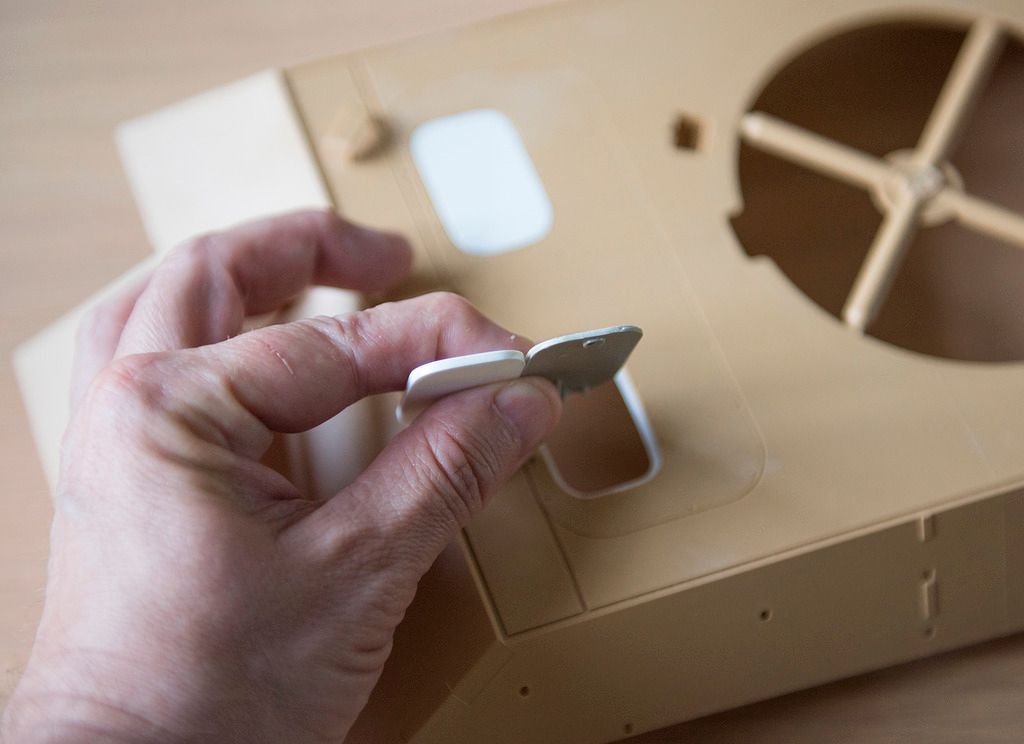

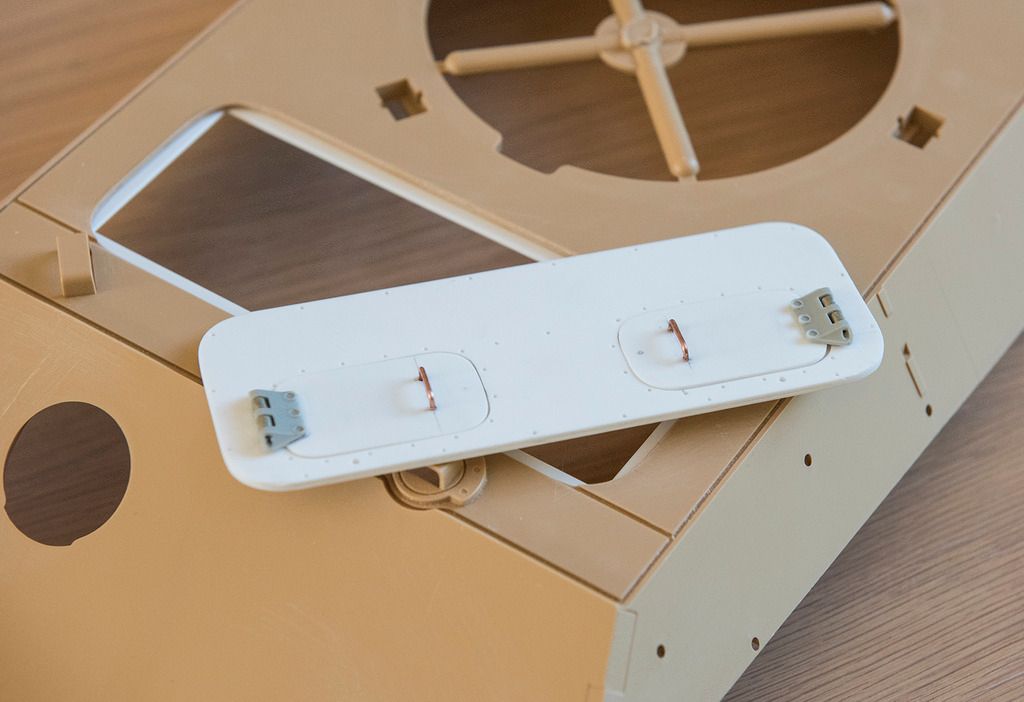

This Aber photo etch set took another day of soldering but is, I think, infinitely better than the kit part. Again all the clasps work and although occasionally frustrating I think the extra work was really worth it.

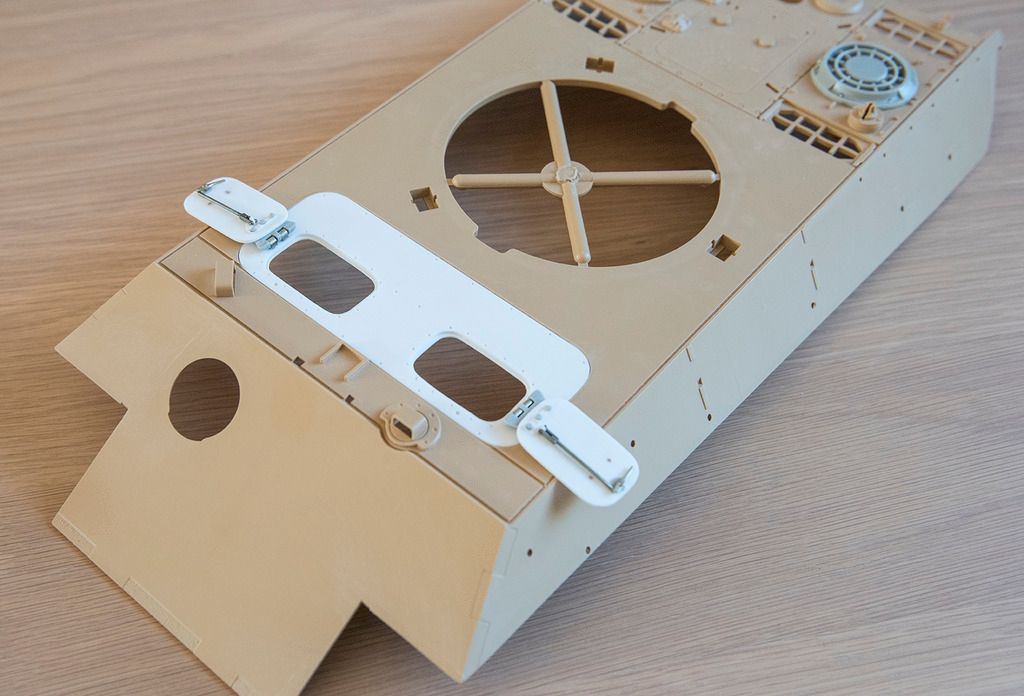

Here's a few pics...

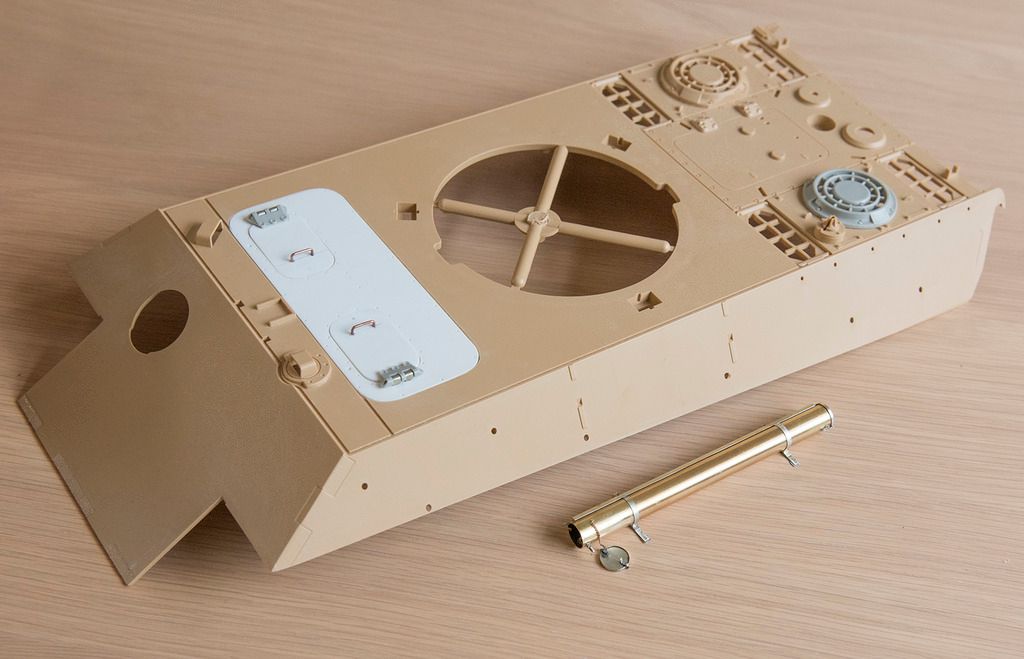

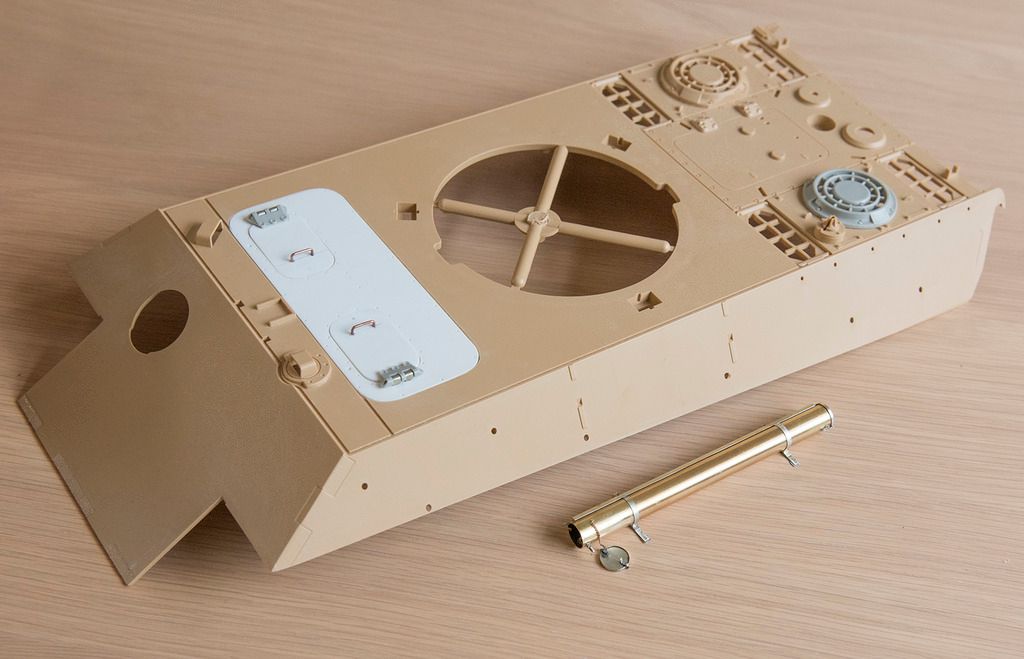

The kit part for comparison...

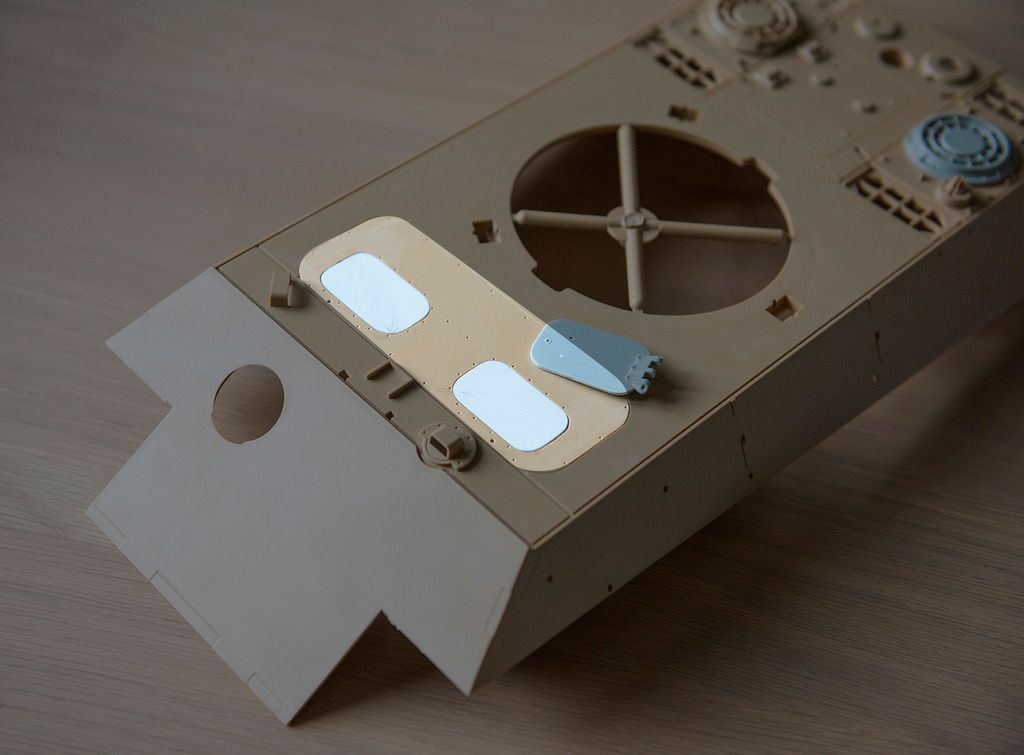

And the part below where it will eventually be positioned on the tank...

Next...

More soldering I'm afraid with tool brackets, fire extinguishers, jacks etc on the menu!

Till next time

Paul