Next, the blowoff panels and anti-slip coating.

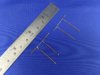

The panels were simply cut from 0.75 mm plastic card, 37 mm long and 57 mm wide. The front-to-back length is based on the size of the autoloader magazine in technical drawings in the books I mentioned earlier, the width is simply pretty much the largest that will fit comfortably on the roof. I then cut that piece into three sections, the smaller ones 10 mm wide each, to mimic the early M1 Abrams style; the space between them is the thickness of my steel ruler

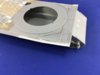

You can also see that I added plastic card in the hole for the remote turret, because Dragon doesn’t provide anything there at all, and you would be able to see straight into the main turret. I curved a 16 mm wide strip of 0.25 mm plastic card and glued it to the inside of the turret, with another piece of plastic card underneath to create a floor. It would have been smarter to do this before glueing the top and bottom halves of the turret together, though.

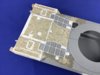

I then taped off the outlines of most of the areas that were to receive an anti-slip coating:

That just left finding a good way to actually make it

I began by experimenting on an offcut of plastic card, painting the attempts to see what they would look like when done:

At the top is filler putty stippled with a cut-down brush, which looks OK, the smooth area below that is Mr. Surfacer 1000 stippled with the same brush (I would have used the thicker 500, but my pot of it had dried out), and below that is acrylic gel with sand sprinkled into it. That’s the option I went with:

Step by step, here’s the front turret with gel applied using a spatula, trying to get an even coat:

The coat doesn’t need to be perfectly flat, though, as the gel shrinks a bit as it dries and so the bumps tend to even themselves out.

Next, sand sprinkled on using the tea strainer to get rid of the large pieces, hairs, etc. that inevitably end up in an open box of sand sitting in your modelling room for decades

I just shook the turret over the box again to get rid of the loose excess.

And finally the tape carefully removed to prevent lifting the gel:

More areas still need doing, but the tape for the others got in the way so it was just simpler to do it in multiple steps.

Note that I’m using beach (sea) sand here, not river (construction) sand. River sand is typically coarser, while beach sand is very fine and much more suitable as an almost-in-scale texture. I think fine sand can also be purchased from pet shops, for use in bird cages, but if you live near the sea you may be able to just go get some for free

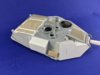

On the German version, the sponsons (the areas above the tracks) are basically wedge-shaped, tapering from very thin at the front to full thickness above the third roadwheel, with an ever narrower mudguard alongside. On the American tanks, the sponson doesn’t taper, but begins at full thickness above the second roadwheel, and the mudguard seems to be full-width but sits underneath the stowage bin until that point. Compare the hull to the drawing in this photo:

On the German version, the sponsons (the areas above the tracks) are basically wedge-shaped, tapering from very thin at the front to full thickness above the third roadwheel, with an ever narrower mudguard alongside. On the American tanks, the sponson doesn’t taper, but begins at full thickness above the second roadwheel, and the mudguard seems to be full-width but sits underneath the stowage bin until that point. Compare the hull to the drawing in this photo: