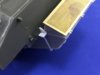

That blast shield is a scratchbuilding job in its own right … I intended to use Resicast’s parts for the front supports, that attach around the forward of the two round beams, but noticed a major mistake in Resicast’s instructions. Here is how they would have you fit the front supports, parts CM:

Later on in the instructions, though, there’s this photo of a real Crab (the one at Overloon, before it was moved indoors):

Spot the difference?

If you thought: the pieces of angle iron are

behind the beam here, but the CM parts are in front of it on their model, then you noticed the same thing I did

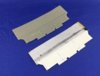

Looking closer at the parts, they’re also made the wrong way round, so that the angle iron is mirrored if you put the CMs on the correct side. Everything together, making them from scratch would be simpler than trying to use the kit parts. Luckily, I found a piece of plastic L-angle of the right size in my collection of scratchbuilding materials, so worked out how long each support needs to be (15 mm) and drilled two holes through for the copper wire bracket, then filed a round bit out of the plastic to accommodate the beam.

Here are the parts I made, plus those supplied by Resicast for these supports:

You may notice the set gives plenty of spares, which I’ve found to be typical of Resicast, and to be highly applauded in the hope that other resin kit manufacturers follow this example. Some bits

will break or fly off into oblivion, so you can usually still complete a Resicast kit if this happens to one of the more minor parts.

One support is already on the beam because I made that one yesterday to work out how, the other three today because the first one was so fiddly that I didn’t feel like doing the rest anymore yesterday night

The other three went together more easily. Attaching them to the beam was easy enough: just bend the copper wire around it, stick the ends through the holes in the plastic strip, push everything together as far as it will go, then add a few drops of superglue to secure it all. I still have to cut the wire to length, but will wait for the glue to dry.

I don’t think I’ll add a bit of strip and bolt heads on these, unlike on the blast shield, because they will be barely visible, if at all, and the protruding ends of the copper wire will probably do to give the impression of a bolt being there anyway.

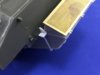

I also completed the deep-wading trunk on the hull rear:

Mostly just adding grab handles (more copper wire) and locking handles (supplied with the Resicast trunk set) and a few other bits and bobs. I did have to make a new hull bracket for the left side:

This was because when I tried to glue the resin part into place, I knocked it off with my tweezers and it disappeared

Unfortunately, of course, this is one they didn’t supply a spare of, unlike the handles for example. Oddly, though, this wading trunk set does include plenty of parts that aren’t even mentioned in the instructions for it.

...

...

Unfortunately, of course, this is one they didn’t supply a spare of, unlike the handles for example. Oddly, though, this wading trunk set does include plenty of parts that aren’t even mentioned in the instructions for it.

Unfortunately, of course, this is one they didn’t supply a spare of, unlike the handles for example. Oddly, though, this wading trunk set does include plenty of parts that aren’t even mentioned in the instructions for it.