These lengths of wood are going to be sanded down to create a slightly rounded area within the pencil marks, to give a sort of 'waist' to the poles. These poles will be set vertically in front of the front area seats and will have hand hold bars attached.

Sanding...

Sanded. The effect is subtle yet noticeable when set in place:

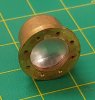

1 mm holes are then drilled part way through each post, ensuring that each row of holes are lined up according to the instructions. Into these holes will go the hand hold brass ends:

The poles are inserted into the base and horizontal beams are attached to the front top piece. Some rubber parts will require sorting at the base of the poles:

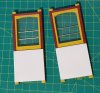

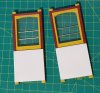

These thin strips are to be painted the red shade and will be attached to the sides of the front panels to neaten them up. The poles and horizontal beams are also varnished:

1 mm holes are also drilled into the new strips, in line with the pole holes. The hand hold bars on these front panels will be full length, into the holes you see in the picture above in the front bumper.

Rod strips that will make up the hand hold bars, along with other upcoming pieces that will need to be white, are painted

Each hand hold bar is made up of two brass ball ends, and a length of the white painted rod strip. The brass ball ends are inserted into the 1 mm holes:

The front hand hold bars proved troublesome. The rod is slightly larger than the brass ball ends, so some trimming was required. As the lower brass ball end sits half way up the front poles, this meant some touching up with a paint brush after repairs were made. The result at the end of all this: