Not done much for a while, but I did some more work on the bow now.

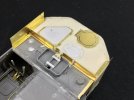

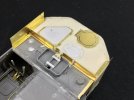

The etched hatch you get in the LZ kit has about the right size and shape, but its lid is noticeably too thin, so I added a bit of plastic card to raise it up a bit. LZ’s base for the capstan is far too large, though — it’s the etched part towards the front (and loose), with its plastic card and rod replacement in the correct position.

LZ also doesn’t give you any supports for the transverse etched piece, so I made them from some plastic strip. They were not placed symmetrically on the real M29C.

Then the surf guard:

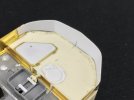

As I had already discovered on my last attempt, LZ’s etched part doesn’t fit, so I used the same method now as then to find the right shape: I taped a piece of paper to the bow and marked out its contours. After cutting it out from the paper and pasting it to 0.25 mm plastic card, I cut it out, bent it to shape, and superglued it to the bow.

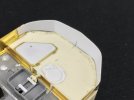

Here’s my template on the etched part by how much the two differ:

It’s not perfect (and, in fact, not quite symmetrical) but at least it fits reasonably well, unlike the etched part.

,looks superb!!

,looks superb!!

My surf guard is a little uneven, but you only really see that from above, so I will claim it got dented, and that’s what I’m sticking to

My surf guard is a little uneven, but you only really see that from above, so I will claim it got dented, and that’s what I’m sticking to