S

Sky Raider

Guest

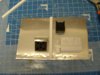

Well gang, here we go with the build process pic. i have many now as i am about 6 week into it. At this point i will show you just a few and then upload more as time goes on if you are still interested.

Andy

A breif insight for you gang. The first picture shows the general layout for the rear fin. The struts are glued to the leading edge and the trailing edge, then the skin is applied, we use glue called Zap and it is as good as its name. There is instant Zap and 2 Minute Zap. Zap is even stronger and faster than super glue... once both surfaces are connected thats it. This is why we use 2 minute Zap for areas that need a little fiddleing with. The fin rudder isnt cut away from the fin until the skin has been applied. This keeps everything in line, for this we use a Razor Saw, very fine and very good for tigh gaps. Before the ribs are fitted it is advised to pin the rails to a flat surface this will reduce the risk of any twisting in the fuse, once this is done the ribs are fitted to the rails and Zapped in place. Pic 6 shows the ribs, rails and part skin fitted. Ignore this pic it is a little in front, my next upload will show you exactly how we get to this stage. Stay tuned for the next episode.

Andy

View attachment 17399

View attachment 17400

View attachment 17401

View attachment 17402

View attachment 17403

View attachment 17404

View attachment 17405

View attachment 17406

View attachment 17407

View attachment 17408

Andy

A breif insight for you gang. The first picture shows the general layout for the rear fin. The struts are glued to the leading edge and the trailing edge, then the skin is applied, we use glue called Zap and it is as good as its name. There is instant Zap and 2 Minute Zap. Zap is even stronger and faster than super glue... once both surfaces are connected thats it. This is why we use 2 minute Zap for areas that need a little fiddleing with. The fin rudder isnt cut away from the fin until the skin has been applied. This keeps everything in line, for this we use a Razor Saw, very fine and very good for tigh gaps. Before the ribs are fitted it is advised to pin the rails to a flat surface this will reduce the risk of any twisting in the fuse, once this is done the ribs are fitted to the rails and Zapped in place. Pic 6 shows the ribs, rails and part skin fitted. Ignore this pic it is a little in front, my next upload will show you exactly how we get to this stage. Stay tuned for the next episode.

Andy

View attachment 17399

View attachment 17400

View attachment 17401

View attachment 17402

View attachment 17403

View attachment 17404

View attachment 17405

View attachment 17406

View attachment 17407

View attachment 17408

Last edited: