- Joined

- Apr 28, 2018

- Messages

- 6,212

- Points

- 113

- First Name

- Bob

Afternoon all

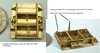

The Daring has very fine ladders, these are causing me a big headache lol

I first used masking tape to support them on the fret but when using a blade to remove them they still deformed, i then tried using snips, better but then had the problem if trying to remove the nub from the fret. Its so thin and fine any pressure deforms it out of shape

Can anybody help with how they get around this problem

Thanks bob

The Daring has very fine ladders, these are causing me a big headache lol

I first used masking tape to support them on the fret but when using a blade to remove them they still deformed, i then tried using snips, better but then had the problem if trying to remove the nub from the fret. Its so thin and fine any pressure deforms it out of shape

Can anybody help with how they get around this problem

Thanks bob