Hey everyone

Does anyone remember this? If you do you've got some memory!

I won't go into too much detail but the reason for the long pause in this build was mainly down to moving house and relocating to my native Yorkshire. Now I'm settled into my new house, with my new studio (a criteria for the house purchase was to give myself a dedicated model space!) I can, finally, get back to some model builds.

For those who are new to the forum, or those that don't remember where this left off I'm going to do a little recap with shots uploaded to this site (no photobucket deletions this time!) This will also jog my memory and help me to see how far I'd got with this big Panther build. I do have an update so new shots will come but until then here's a reminder of the journey so far...

First the kits and aftermarket stuff

Suspension arms, torsion bars and lower hull construction...

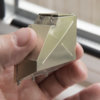

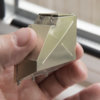

The photoetch stowage bins from Aber

These are a vast improvement on the kit parts, and the working latches (although extremely fiddly) are awesome...

Then came the fenders...

To be continued...

I'll post this now as I'm aware this is a picture heavy thread and will resume in the next instalment.

I hope this is of interest. I have plans for my large scale armour projects and it will be good to share my journey with you guys.

As always any comments are very welcome.

Cheers

Paul

Does anyone remember this? If you do you've got some memory!

I won't go into too much detail but the reason for the long pause in this build was mainly down to moving house and relocating to my native Yorkshire. Now I'm settled into my new house, with my new studio (a criteria for the house purchase was to give myself a dedicated model space!) I can, finally, get back to some model builds.

For those who are new to the forum, or those that don't remember where this left off I'm going to do a little recap with shots uploaded to this site (no photobucket deletions this time!) This will also jog my memory and help me to see how far I'd got with this big Panther build. I do have an update so new shots will come but until then here's a reminder of the journey so far...

First the kits and aftermarket stuff

Suspension arms, torsion bars and lower hull construction...

The photoetch stowage bins from Aber

These are a vast improvement on the kit parts, and the working latches (although extremely fiddly) are awesome...

Then came the fenders...

To be continued...

I'll post this now as I'm aware this is a picture heavy thread and will resume in the next instalment.

I hope this is of interest. I have plans for my large scale armour projects and it will be good to share my journey with you guys.

As always any comments are very welcome.

Cheers

Paul

Last edited: