- Joined

- Apr 28, 2018

- Messages

- 10,791

- Points

- 113

- First Name

- Jakko

Some years ago, I wanted to add an A30 Challenger tank to my 1/72 scale British 1944–45 wargaming troops. Since it’s a straightforward vehicle, I decided to convert it rather than seeing if anyone made a model of it.

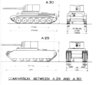

First, though, some history to put it into perspective. The British had developed the 17-pounder gun and wanted to mount it into a tank, eventually deciding to base it on the Cruiser Tank Mk. VII Cromwell (A27). Two designs were trialled and put into production: the open-topped Self-Propelled Gun Avenger (A30) and the Cruiser Mk. VIII Challenger (A30). Both used a lengthened Cromwell hull with six roadwheels instead of five, with a completely new turret and other changes. As the designations indicate, the Challenger was intended as a tank while the Avenger was meant to be a tank destroyer in the vein of the American M10 (not “Wolverine”). Challenger went into production in time to be used in Normandy, though only from about August, but Avenger production really only got underway after the war.

This is Challenger:

And this is Avenger:

Challenger has a crew of five: commander, gunner, two loaders and driver. It was mainly issued to units equipped with Cromwells, with one Challenger attached to each tank platoon in the same way that a 17-pounder-armed Sherman was attached to Sherman platoons (and, until Challengers became available, to Cromwell platoons as well).

For my model, I decided to use two Revell Cromwell Mk. IV kits:

This is a model I would certainly recommend. It's well-detailed and accurate, with link-and-length tracks (if somewhat fiddly), and inexpensive at something like €13 each (I think I paid). Here’s what you get in the box (aside from decals etc.):

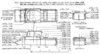

Since Challenger had a longer hull thank Cromwell, I needed to lengthen it, which is why I needed two kits. I began by chopping up the hulls:

I worked out where to cut by scaling a side-view drawing of the real tank to 1/72 in Adobe Photoshop and using the measuring tool in it so I could work out the distances between the wheels. There was a reason I couldn’t do this more simply by taking the front three stations of one hull and the rear three of another, but I don’t remember what it was I think, but am not sure anymore, that the spacing will be off if you try it that way.

I think, but am not sure anymore, that the spacing will be off if you try it that way.

Next, I cut the outer hull panels (these cover the springs on the real tank) to match, resulting in this set:

That done, I combined the hull parts by taking the all the ones with two axles and adding plastic card on the inside:

This took a lot of care to get things straight, because I didn’t want a warped hull, but it worked out in the end. Here it is with the wheels and tracks on:

These didn’t need any cutting. I just had to take more of the shorter lengths, and perhaps some single links, per side than necessary for Cromwell, and it all fit fine.

First, though, some history to put it into perspective. The British had developed the 17-pounder gun and wanted to mount it into a tank, eventually deciding to base it on the Cruiser Tank Mk. VII Cromwell (A27). Two designs were trialled and put into production: the open-topped Self-Propelled Gun Avenger (A30) and the Cruiser Mk. VIII Challenger (A30). Both used a lengthened Cromwell hull with six roadwheels instead of five, with a completely new turret and other changes. As the designations indicate, the Challenger was intended as a tank while the Avenger was meant to be a tank destroyer in the vein of the American M10 (not “Wolverine”). Challenger went into production in time to be used in Normandy, though only from about August, but Avenger production really only got underway after the war.

This is Challenger:

And this is Avenger:

Challenger has a crew of five: commander, gunner, two loaders and driver. It was mainly issued to units equipped with Cromwells, with one Challenger attached to each tank platoon in the same way that a 17-pounder-armed Sherman was attached to Sherman platoons (and, until Challengers became available, to Cromwell platoons as well).

For my model, I decided to use two Revell Cromwell Mk. IV kits:

This is a model I would certainly recommend. It's well-detailed and accurate, with link-and-length tracks (if somewhat fiddly), and inexpensive at something like €13 each (I think I paid). Here’s what you get in the box (aside from decals etc.):

Since Challenger had a longer hull thank Cromwell, I needed to lengthen it, which is why I needed two kits. I began by chopping up the hulls:

I worked out where to cut by scaling a side-view drawing of the real tank to 1/72 in Adobe Photoshop and using the measuring tool in it so I could work out the distances between the wheels. There was a reason I couldn’t do this more simply by taking the front three stations of one hull and the rear three of another, but I don’t remember what it was

I think, but am not sure anymore, that the spacing will be off if you try it that way.

I think, but am not sure anymore, that the spacing will be off if you try it that way.Next, I cut the outer hull panels (these cover the springs on the real tank) to match, resulting in this set:

That done, I combined the hull parts by taking the all the ones with two axles and adding plastic card on the inside:

This took a lot of care to get things straight, because I didn’t want a warped hull, but it worked out in the end. Here it is with the wheels and tracks on:

These didn’t need any cutting. I just had to take more of the shorter lengths, and perhaps some single links, per side than necessary for Cromwell, and it all fit fine.

, but impressive just the same.

, but impressive just the same.