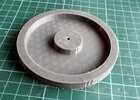

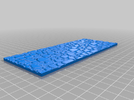

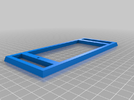

As you may have read, I've commissioned my Anet A6. I've printed out the benchies & calibrations, and now I'm going to use the printer as an extension of my model making. There are existing models, that could be useful. One of these I did print out, a track link jig - it printed OK, but it wasn't any good for anything other than very wide tracks - think Tiger+! There is a jig for holding assembled aircraft, which looks a bit weedy. In general, I think these models were made for a specific purpose, and don't look too useful for other models. At the moment I'm just thinking of assembly aids or jigs, the first being a propeller alignment jig, for 2,3,4 & 5 bladed assemblies, the second being a jig for tank track individual links with various widths and configurations. Among another ideas are a painting jig to hold tank/lorry roadwheels, without using those pesky masks. Further down the line - dockyard bases for 1/350 ships - seascape bases for dioramas, box loads for trucks - there are quite a few more ideas, but I'd better learn to walk before I run. This may take some time - prototyping can be a long drawn out process.............

Dave

Dave