Gary MacKenzie

SMF Supporter

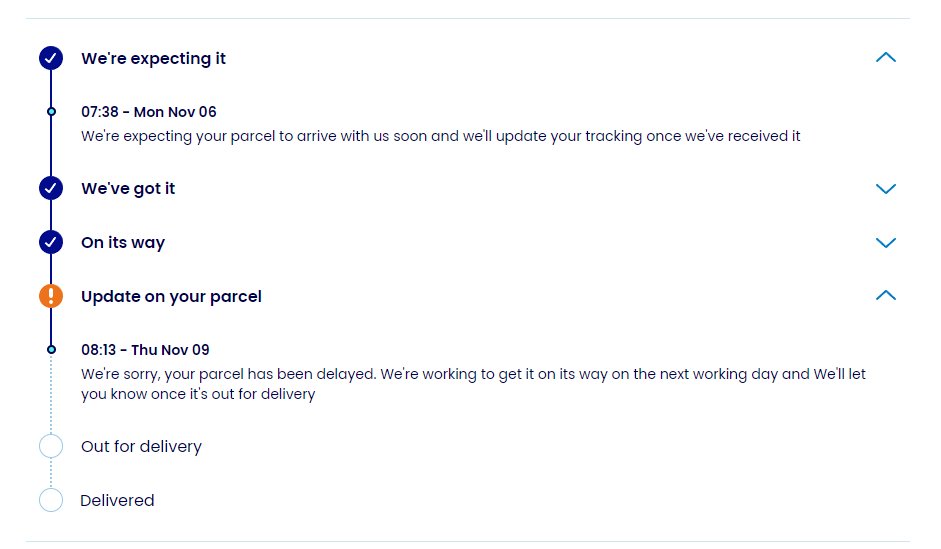

Been messing with ''tinkercad'' too , which is more visual program, but aparently uses different logic.

With openscad each command is processed , then the next , in order you have them on the program list

so moving a piece up or down the list alters how it interacts with other pieces

In tinkercad for example , a hole overrides everything else, no matter when you added or deleted a piece, unless I am missing a way to lock pieces so that other things don't interact with them.

Now down the youtube rabbit hole watching tinkercad videos

Ok , different logic , a "group" is the solution , group two or more pieces including hole , and it becomes 1 logical piece so that hole in it doesn't affect other pieces.

With openscad each command is processed , then the next , in order you have them on the program list

so moving a piece up or down the list alters how it interacts with other pieces

In tinkercad for example , a hole overrides everything else, no matter when you added or deleted a piece, unless I am missing a way to lock pieces so that other things don't interact with them.

Now down the youtube rabbit hole watching tinkercad videos

Ok , different logic , a "group" is the solution , group two or more pieces including hole , and it becomes 1 logical piece so that hole in it doesn't affect other pieces.

Last edited: