CHAPTER I - Cabin & bubble canopy construction

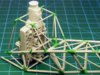

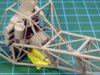

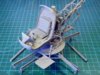

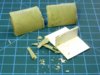

To produce a thin-skinned, right-to-scale cabin, a solid rock one-piece "image cast" of the bubble typed cabin should be made of modeling clay & epoxy first and then try to reproduce a copy by vacuum forming the image cast. Using the following modeling clay item, found in my local supermarket. It's an air-drying modeling clay ideal for scale modeling and shaping. According to the instructions, it can be easily formed into shape, become solid rock withing few hours, re-filled or sanded if necessary and painted or lacquered. That sound quite good to me and similar to the well known Milliput epoxy putty, with the only difference that the 500g air-drying modeling clay pack cost only 1£, instead of 100g Milliput epoxy putty which cost 5£. That makes the new found air-drying modeling clay, about 25 times cheaper than Milliput epoxy putty and that's a good reason for me to give it a chance.

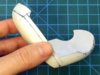

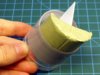

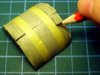

I formed the basic shape of the bubble typed cabin, by picking small quantities of this modeling clay with a metal spatula and applying the air-drying modeling clay. It felt too soft and very easy to spread the material nicely. I didn't want to care too much and try forming and shaping the clay, because I was planning to add epoxy putty and sand to make a nice shinny finish. After all, I had no idea how much available time I had, before the material start becoming hard and difficult to handle.

The specific polyester filler I used to apply over the clay, comes with the proper catalyst which provides a solid rock build and approximately 3 to 5 minutes time window to form it into shape. I prefer to use epoxy putty or polyester filler with fiberglass grains for special purposes, because:

- It becomes solid rock within only few minutes or seconds,

- it does not shrink and does not crack after months or years,

- you can pour to any shape that you want but you need to work fast because as soon as you mix it with catalyst cream approx 5%, you have limited time before becoming solid rock,

- you can also put additional layers of epoxy or polyester filler to build up,

- you can sand it, you can drill it, you can use any type of scale modeling glue, any type of primer or enamel / acrylic paint on it with no problem,

- can be purchased at any good crafts store into 250ml, 500ml, 1lt (comes with a tube of catalyst hardener) or bigger canisters and if you can't find it, fear not and try your local decent hardware store and finally...

- it is cheaper than dirt - estimated prices are £3 to £10 depending the canister size, the quality, if contains fiberglass grains for maximum strength etc.

Keep in mind that the chemical reaction after mixing the polyester filler with the catalyst hardener, produces some heat that possibly effect on thin plastic parts, so test it first before try it on your scale model. I don’t think that the produced heat is more than Fahrenheit 110, but better watchout. Remember that epoxy materials are dangerous when breath or shallow and could result skin, eyes or lungs problems or even cancer when used for long period with no precaution measures. Always keep in mind, that a powerful vacuum system to suck away the epoxy dust should be used all time to keep the workbench area clean while sanding or milling epoxy or resin materials. Using an issued breathing mask and a pair of surgery latex gloves to prevent dust contact with lungs and fingers while sanding or milling epoxy, is also an important matter that you should seriously take care of! My recommendation is to also wear an overall working suit (as I do) to keep your clothes dust free while sanding epoxy. Some people might find it too much, but I wouldn't like to bring epoxy dust & grains from my work bench into living room and my beloved.

As long as this subject relates to our physical health and the physical health of all family members and loved ones who may come into contact with the materials we use in scale modeling, we need to be very careful and suspicious. We all need to be informed on whether it is safe or not about the materials used in scale modeling and what can we do to avoid or minimize the risks of everyday contact. Some of you may wonder if the epoxy putty or dust from the epoxy sanding is actually hazardous to health or if it really causes harm to human body. Some might say that all these are just an urban legend and a pseudo story based on Goebbels theory that has finally become accepted as an illusionary reality. Some might even support the view that these products had passed controls and been inspected by independent and non-controlled health organizations and committees and that if these products were truly dangerous, the companies would not be allowed to produce and would never be free sold in usual drugstore, where ordinary Joe might buy it. Well, should we sleep quietly at night, knowing that anything surrounds us, are truly inspected by independent and non-controlled health organizations and committees? Should we or not? Because as far as I know, the same organizations and committees are those that allow the free sale and use of other products such as cigarettes, asbestos sheets, hazardous petrochemicals etc to millions ordinary Joes daily! Should, I assume that this situation might happens, because nobody has informed them that such products, do kill slowly and painfully? On the other hand, there are thousands of publications in medical conferences and seminars to warn of the dangers that may cause the powdered epoxy resin and the dust produced from the epoxy resin sanding. There are thousands of studies showing a direct relationship of lacquer solvents, toluene thinner, thixotropic agents etc, with serious damage to the human body - including cancer. Is it a well organized theory by Goebbels himself? Surely no! Should we ignore all these warnings? Should we believe that the good companies who only care about consumer’s health and not bothered about the ephemeral economic gain at the expense of our health, check everything thoroughly and would never allow dangerous products in the open market?

Some of you may consider an exaggeration to suggest the use of breathing mask, latex gloves and special clothing during the epoxy materials processing, but let me explain my point of view, within only few words.

- Having survived by the 1986 radioactive fallout of Chernobyl, which dramatically increased the incidence of deaths due leychamia in Northern part of Greece where I grew up and having lost 2 of my classmates from school because this reason,

- Having suddenly acquired (me and tens of thousands of fellow citizens in my town, at the exact same time) some strange allergies occurred in the late 90ies, just after the Allied uranium shells bombing in Serbia, which is just few kms away from the city I live,

- Having lost at the age of 46yo, my mentor in scale modeling and good friend who (coincidentally?) worked continuously in an environment saturated with epoxy resin powder & lacquer thinner fumes,

- Having lost a second very good friend and highly skilful figure and miniature builder (perhaps the best in Greece at that time) for similar reason...

…I think it’s not so good idea to keep pushing my luck and I decided to follow some protection rules. Under no circumstances I propose to live the rest of our lives locked in a sterile glass - this would not be life. I would strongly suggest to live our life as intensely as possible. But keep in mind, that the wise parachutist, always checks thoroughly his main & reserve gear before each jump and does not behave casually leaving his life to luck factor, just because he was lucky so far and didn’t happen to face an emergency. "SAFETY FIRST " became my personal logo and whoever wants, is free to follow.

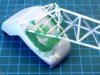

When the cast used as an "image" of the bubble typed cabin, was filled with a layer of polyester filler and had enough time to polymerize and get solid rock, it was sanded carefully to get the right shape. Finally, the cast was sprayed with white shiny finish to help me spot any scratches or defects.