hi IC

i `ve had a quick look about but no pics are to be found !

could you post a pic of the hull innards , and then we`ll maybe come up with something,

but here`s how it normally runs on fast electrics...

there is a water pick up aorung the prop ( normally right behind the prop)

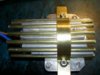

this picks up water and it is the carried by small bore hose ( like ic car fuel pipe) to a cooling coil, this is a pipe that is twisted arond the motor various times. made of alloy or copper for good heat transfer. i have made them in the past with (car) brake pipe ( the soft stuff) and clear washer hose. so you can see the water flow.

depending how you feel up to it . you can make a coil or buy one, if you know the size of motor fitted. after the coil the water flows through another short pipe to (normally) the side of the hull and flows back to the pond. this is just a quick run thorugh,

http://www.astecmodels.co.uk/

astec are a fast electrics specialist , with a decent website, and i believe very helpful, however i have never personally used them.

Adz..