Panzerwrecker

SMF Supporter

- Joined

- Mar 2, 2022

- Messages

- 362

- Points

- 93

- First Name

- Los

Anyone wishing to model a 1/35 mobile German Flak 3.7cm 18/36/37/43 will find it difficult finding one of the Sd.Ah 56/57 ammunition trailers commonly towed by these vehicles. When it came to trailers the Germans made many http://www.kfzderwehrmacht.de/Homepage_english/Trailers/Special_trailers/special_trailers.html and the smaller 2cm Flak trailer like the Sd.Ah 51 for example can be found as additions to the Flak gun kits made by Dragon and Tamiya and even as a standalone kit by Bronco. Finding an accurate Sd.Ah 56/57 is a little trickier.

Discounting the trailer that Trumpeter includes in many of its mobile Flak kits (more on that later), the only option from a model company is Wiener Modellbau's resin kit. https://www.scalemates.com/kits/wie...05-munitions-sonderanhaenger-sdah-57--1168423 This is getting harder to find these days and although it is a close overall rendition it is very simplified and has some very noticeable and obvious errors.

This is what the real thing looked like. There are a few variations in the box design and wheels, but all were built on the same single axle 1.5T chassis. The earlier models have a curved roof and later models appear to have been simplified and come with a flat roof with less locker door hinges (material savings no doubt)

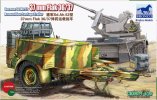

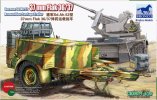

As already mentioned Trumpeter includes a trailer in many if not all their Sd.Kfz 7 Flak variants and although they call it an Sd.Ah 52 the actual model is nothing like the real thing. The chassis is a close enough resemblance, but the box structure is pure make believe!

Compare Trumpeter's offering below and Bronco's Sd.Ah 52 which is a much more accurate of the real thing.

So what if scratch building is not your thing and you want to depict an Sd.Ah 56/57? Well if you have access to a 3D printer you are in luck. Download the 3D file from fellow modeller Darius Stucinskas online at https://cults3d.com/en/3d-model/various/1-35-scale-sd-ah-56-57-ammunition-trailer

The kit is exquisite and although there is a lot of support material clean up involved once that is out of the way you are left with a beautifully accurate scale model.

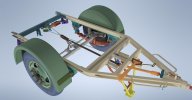

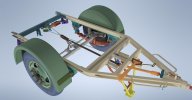

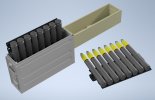

Check out these CAD images

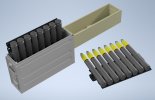

Now whilst I really wanted to portray this Sd.Ah trailer I was a little intimidated by the clean-up process that a 3D print would involve. The number of tiny parts would also be a challenge, not to mention hoping the design work would mean the kit was engineering to all fit together well. Well, there really is nothing to worry about folks, this is the future. Darius has done a fabulous job in all his research and design work. Admittedly he acknowledges there are a few areas that he cannot be 100% sure about. Whether the box floor had wooden slats or whether the sliding dividers were a standard feature for example. What he can be sure of, is the kit is dimensionally accurate and all the parts will fit flawlessly together. Right down to the working and sliding support stands, the handbrake assembly and all the nuts and bolt you install just like the real thing. It is advisable to clean up the parts whilst they are supported and clean up all the holes with micro drills as this will make for a much more pleasurable and straight forward build. There are two rear chassis frame designs each with their own leg supports style and different tyre and wheel options can be had. Likewise, ammunition and ammo cases for both the 2cm Flak 38, Flakvierling 38 and 3.7cm Flak 36/37/43 are available.

I will be building two trailers. One I will model as being towed and one which will be sat on its own stands with the locker doors open displaying all the stowed ammo and crew paraphernalia

Work in progress has started on the towed trailer and although there are a few areas that could be improved upon (my fault and not the kit) I aim to remedy these issues on the second build. One of them is the wire I used to make the handbrake cable. I didn't have any 0.3mm as recommended and therefore it doesn’t look straight and stretched enough. I also had difficulty winding down the ends on the rear adjustable bar. Secondly was the amount of CA I used constructing the body. Even with the fine applicator that the Colle21 rubber CA came with, I still managed to apply a little too much. This meant I didn't get quite as tight a fit as I would have liked, and it just knocked the alignment out a touch.

Onwards and upwards though.

Excuse the image quality.

Discounting the trailer that Trumpeter includes in many of its mobile Flak kits (more on that later), the only option from a model company is Wiener Modellbau's resin kit. https://www.scalemates.com/kits/wie...05-munitions-sonderanhaenger-sdah-57--1168423 This is getting harder to find these days and although it is a close overall rendition it is very simplified and has some very noticeable and obvious errors.

This is what the real thing looked like. There are a few variations in the box design and wheels, but all were built on the same single axle 1.5T chassis. The earlier models have a curved roof and later models appear to have been simplified and come with a flat roof with less locker door hinges (material savings no doubt)

As already mentioned Trumpeter includes a trailer in many if not all their Sd.Kfz 7 Flak variants and although they call it an Sd.Ah 52 the actual model is nothing like the real thing. The chassis is a close enough resemblance, but the box structure is pure make believe!

Compare Trumpeter's offering below and Bronco's Sd.Ah 52 which is a much more accurate of the real thing.

So what if scratch building is not your thing and you want to depict an Sd.Ah 56/57? Well if you have access to a 3D printer you are in luck. Download the 3D file from fellow modeller Darius Stucinskas online at https://cults3d.com/en/3d-model/various/1-35-scale-sd-ah-56-57-ammunition-trailer

The kit is exquisite and although there is a lot of support material clean up involved once that is out of the way you are left with a beautifully accurate scale model.

Check out these CAD images

Now whilst I really wanted to portray this Sd.Ah trailer I was a little intimidated by the clean-up process that a 3D print would involve. The number of tiny parts would also be a challenge, not to mention hoping the design work would mean the kit was engineering to all fit together well. Well, there really is nothing to worry about folks, this is the future. Darius has done a fabulous job in all his research and design work. Admittedly he acknowledges there are a few areas that he cannot be 100% sure about. Whether the box floor had wooden slats or whether the sliding dividers were a standard feature for example. What he can be sure of, is the kit is dimensionally accurate and all the parts will fit flawlessly together. Right down to the working and sliding support stands, the handbrake assembly and all the nuts and bolt you install just like the real thing. It is advisable to clean up the parts whilst they are supported and clean up all the holes with micro drills as this will make for a much more pleasurable and straight forward build. There are two rear chassis frame designs each with their own leg supports style and different tyre and wheel options can be had. Likewise, ammunition and ammo cases for both the 2cm Flak 38, Flakvierling 38 and 3.7cm Flak 36/37/43 are available.

I will be building two trailers. One I will model as being towed and one which will be sat on its own stands with the locker doors open displaying all the stowed ammo and crew paraphernalia

Work in progress has started on the towed trailer and although there are a few areas that could be improved upon (my fault and not the kit) I aim to remedy these issues on the second build. One of them is the wire I used to make the handbrake cable. I didn't have any 0.3mm as recommended and therefore it doesn’t look straight and stretched enough. I also had difficulty winding down the ends on the rear adjustable bar. Secondly was the amount of CA I used constructing the body. Even with the fine applicator that the Colle21 rubber CA came with, I still managed to apply a little too much. This meant I didn't get quite as tight a fit as I would have liked, and it just knocked the alignment out a touch.

Onwards and upwards though.

Excuse the image quality.

The L4500 armoured truck is not a model that has been well served in 1/35. There have been a few resin conversions. Trumpeter have recently released a rook of armored Flak versions in plastic.

The L4500 armoured truck is not a model that has been well served in 1/35. There have been a few resin conversions. Trumpeter have recently released a rook of armored Flak versions in plastic.