S

Sky Raider

Guest

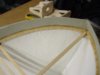

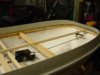

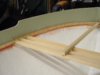

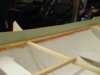

Thanks Jim, the last few days have been a nightmare not having any instructions and scale drawings on what needs to go where.

The deck will be painted grey Colin yes but there is a planked overlay that sits on the top and only covers certain areas, the deck is a mixture of iron and wood... all will be revealed in due course, there will be lots of suprises along the way i hope.\ said:Looking really good mate.I take it you're painting all the decking woodwork and not having it dressed and varnished then?

For FULL Forum access you can upgrade your account here UPGRADE