Scratchbuilder

SMF Supporter

One question I forgot to ask is what phone camera setting do you use for images. I see I am getting the thumbnail images. At the moment 4160x2340. Should it be smaller i.e 2048x1536. It will save a lot of people having to squint. Thanks in advance.

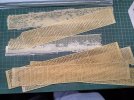

How did you build the masters for the treadway castings? Vast numbers of bits of plastic strip?

How did you build the masters for the treadway castings? Vast numbers of bits of plastic strip?