You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

G

Graham D

Guest

The guns look good. I like the use of the eraser as a soft base for rolling the handrails. I'll try it the next time I need a curved piece of PE

C

Caledonia

Guest

Finished the 28cm Triple Turrets, a combination of kit supplied PE and MK1 PE after market. The kit is short of 2 off Item A6, so I cobbled up something from my scrap box to fit onto one of the Turrets.

View attachment 120282

Will now concentrate on the superstructure, but first I want to assemble the Hull and Deck in order to check the superstructure fit as I go along.

The kit has the option of waterline or full hull, I will be doing the full hull; I understand the fit is pretty poor. Derek

View attachment 120283

View attachment 120284

View attachment 120285

View attachment 120282

Will now concentrate on the superstructure, but first I want to assemble the Hull and Deck in order to check the superstructure fit as I go along.

The kit has the option of waterline or full hull, I will be doing the full hull; I understand the fit is pretty poor. Derek

View attachment 120283

View attachment 120284

View attachment 120285

G

Graham D

Guest

Guns look really good

D

demon

Guest

Very nice progress let us know how the hull fits

I built a uss Benson and that had a practice gun apparently it was used for honing speed of loading and discharging rather than firing watching with interest Derek

Roger

I built a uss Benson and that had a practice gun apparently it was used for honing speed of loading and discharging rather than firing watching with interest Derek

Roger

D

dougie

Guest

those look excellent, the detail is beautiful. Great work in the PE

C

Caledonia

Guest

Hi Roger, as you say used for crew training, I found a photo (see below) of one mounted on Bismark. I never heard of them before.\ said:Very nice progress let us know how the hull fits

I built a uss Benson and that had a practice gun apparently it was used for honing speed of loading and discharging rather than firing watching with interest Derek

Roger

View attachment 120356

As to how the hull fit went, see my next posting below.

Derek

C

Caledonia

Guest

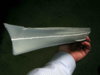

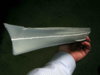

A few shots of the Hull assembly and Deck, first the components.

View attachment 120361

Supplied is a small triangular piece, see below, which is a good idea, as when you fit it to the lower bow section it acts as a guide to ensure both halves of the bow are aligned, it takes a bit of fiddling to get it right, but worth the effort. You need to glue it in position obviously.

If you are using the stand provided for the model, remember to drill the holes from the inside of the Hull, as access is not possible when the Hull halves are cemented together. This applies to the deck also as some holes have to be drilled from the underside before assembly.

View attachment 120359

Before fitting the hull halves together, I did a trial fit of the deck. In order to get a good fit I took a heavy duty craft knife and sliced both ends of all of the diaphragms on order to make the hull wall more flexible. I will leave off the deck until I have the Hull joint finished.

View attachment 120358

Here is the state of the Hull at the moment, to be honest it's not as bad as it looks, about 50% of the joint is perfect, there is two areas both sides where the upper half of the Hull is wider than the lower half. The area at the stern is peculiar in as much as the joints come together perfectly, but unfortunately the plastic turn inward at the joint leaving a valley. This is the first layer of filler, will leave overnight, I used Deluxe's 'Perfect Plastic Putty', applied with a syringe

View attachment 120357

Derek

View attachment 120360

View attachment 120361

Supplied is a small triangular piece, see below, which is a good idea, as when you fit it to the lower bow section it acts as a guide to ensure both halves of the bow are aligned, it takes a bit of fiddling to get it right, but worth the effort. You need to glue it in position obviously.

If you are using the stand provided for the model, remember to drill the holes from the inside of the Hull, as access is not possible when the Hull halves are cemented together. This applies to the deck also as some holes have to be drilled from the underside before assembly.

View attachment 120359

Before fitting the hull halves together, I did a trial fit of the deck. In order to get a good fit I took a heavy duty craft knife and sliced both ends of all of the diaphragms on order to make the hull wall more flexible. I will leave off the deck until I have the Hull joint finished.

View attachment 120358

Here is the state of the Hull at the moment, to be honest it's not as bad as it looks, about 50% of the joint is perfect, there is two areas both sides where the upper half of the Hull is wider than the lower half. The area at the stern is peculiar in as much as the joints come together perfectly, but unfortunately the plastic turn inward at the joint leaving a valley. This is the first layer of filler, will leave overnight, I used Deluxe's 'Perfect Plastic Putty', applied with a syringe

View attachment 120357

Derek

View attachment 120360

D

demon

Guest

Very nice me thinks you have done this before he he one of the reasons why I love modelling scale is doing research and learning things love your idea of the slits in hull spreaders to allow deck to fit right I have that locked into the old grey matter some models are a pleasure to watch being built this is one of them

Roger

Roger

C

Caledonia

Guest

First photo shows the Hull after sanding off the filler, a few areas still need addressing, however they are too shallow for the filler to work effectively.

View attachment 120508

For the finer filling I switch to Mr Surface 500, this is a thick primer which I use to fill the finer faults. The Mr Color Leveling Thinner is used to thin the Mr Surface (as it tends to thicken very quickly in a used bottle), also clean the brush, and clean off any Mr Surface that gets onto unwanted areas of fine detail.

View attachment 120511

I apply two fairly heavy coats to the full length seams with an old brush, and leave to dry overnight, I then sand off with an fine 240/320 Grit Sanding File. Several areas still requires attention, so lighter coats of Mr Surface were applied and sanded, this was repeated several times. The finish now looks good but you can never tell until a primer coat is applied.

View attachment 120509

View attachment 120510

I don't want to prime it yet as I want to drill out the +350 portholes with a 0.7mm drill, which is my next job before fitting the deck. Cheers Derek

View attachment 120508

For the finer filling I switch to Mr Surface 500, this is a thick primer which I use to fill the finer faults. The Mr Color Leveling Thinner is used to thin the Mr Surface (as it tends to thicken very quickly in a used bottle), also clean the brush, and clean off any Mr Surface that gets onto unwanted areas of fine detail.

View attachment 120511

I apply two fairly heavy coats to the full length seams with an old brush, and leave to dry overnight, I then sand off with an fine 240/320 Grit Sanding File. Several areas still requires attention, so lighter coats of Mr Surface were applied and sanded, this was repeated several times. The finish now looks good but you can never tell until a primer coat is applied.

View attachment 120509

View attachment 120510

I don't want to prime it yet as I want to drill out the +350 portholes with a 0.7mm drill, which is my next job before fitting the deck. Cheers Derek

grumpa

SMF Supporter

- Joined

- Jan 14, 2015

- Messages

- 4,691

- Points

- 113

- First Name

- Jim

Just viewed thread so far and am amazed at the almost microscopic ME and plastic, and such clean work for such a tiny scale. 1/35 is too small in my opinion, will be watching though I am not a ship builder but I do want to see your progress.............Jim

- Joined

- May 26, 2009

- Messages

- 13,043

- Points

- 113

- First Name

- Ron

Just had a coffee and a nice time reading this from the start.

Great job Derek. Some really nice work going on, coupled with nice photos, step by step tips and explanations....

Top thread.

Ron

Great job Derek. Some really nice work going on, coupled with nice photos, step by step tips and explanations....

Top thread.

Ron

C

Caledonia

Guest

Thanks Ron, and welcome back, hope you had a great holiday.

Finished drilling out the Hull port holes and fitting the Deck. The first photo shows the lack of definition of the port holes and the second shows the improvement. Note the third photo of the Scharnhorst's anchor way, comparing it to the previous photo it is much more rounded so some cosmetic surgery is necessary.

View attachment 120674

View attachment 120676

The deck was a good fit, the slots previously mentioned in the diaphragms helped with the fit. There is a gap between the two deck sections, I checked the deck housing fit beforehand and there is no problem with this gap. I will sand down some 1x2mm Evergreen strip and fill it in.

View attachment 120672

Cheers Derek

View attachment 120673

View attachment 120675

Finished drilling out the Hull port holes and fitting the Deck. The first photo shows the lack of definition of the port holes and the second shows the improvement. Note the third photo of the Scharnhorst's anchor way, comparing it to the previous photo it is much more rounded so some cosmetic surgery is necessary.

View attachment 120674

View attachment 120676

The deck was a good fit, the slots previously mentioned in the diaphragms helped with the fit. There is a gap between the two deck sections, I checked the deck housing fit beforehand and there is no problem with this gap. I will sand down some 1x2mm Evergreen strip and fill it in.

View attachment 120672

Cheers Derek

View attachment 120673

View attachment 120675

L

Lance B

Guest

Thank you for all the updates, Derek. These look fantastic, great work!

C

Caledonia

Guest

The Anchor Way set me a few problems as regards its geometry. A lot of modellers I found when Googling tend to build up this area to a bulbous shape. I am not convinced that this is correct. If you look at the first two photos, to me there is no deviation from the hull plate plane. I may be wrong but that's what I am going for, so the last two photos show the results. Dragon have obviously got the position of the port holes wrong as they are too high.

View attachment 121592

I wanted to investigate what impact the 1mm error Dragon made regarding deck lengths had on the superstructure, so I made up the basic first level of the three superstructure sections.

The first section Detail 13 on the plans had a few points to note.

For Item N28 read N28+N30

For Item N30 read N30+N31

Be careful of your assembly sequence, K3 has to slip into the tapered sections of K22+K25 and K23+K26

I like to drill out the port holes as I did with the hull.

There are four doors, to fit the kit comes with the option of plastic or brass, I chose brass as the detail is better. But the doorway is hollowed out so a I used a very small amount of blue tack to hold the brass in position whilst I apply thin CA.

View attachment 121590

This photo shows the first level of all three superstructures in position.

View attachment 121589

This photo shows an error on the kit where the margin rail has been missed out, and I have used some Evergreen to replace it.

View attachment 121588

I found it easier to lose the 1mm deck length error between the forward and mid-section of the superstructure, I had to trim the semi-circular deck sections just forward of the pencil. Bear in mind I am using a wooden deck so it is an easy matter to hide the mismatch.

View attachment 121587

Derek

View attachment 121591

View attachment 121593

View attachment 121594

View attachment 121595

View attachment 121592

I wanted to investigate what impact the 1mm error Dragon made regarding deck lengths had on the superstructure, so I made up the basic first level of the three superstructure sections.

The first section Detail 13 on the plans had a few points to note.

For Item N28 read N28+N30

For Item N30 read N30+N31

Be careful of your assembly sequence, K3 has to slip into the tapered sections of K22+K25 and K23+K26

I like to drill out the port holes as I did with the hull.

There are four doors, to fit the kit comes with the option of plastic or brass, I chose brass as the detail is better. But the doorway is hollowed out so a I used a very small amount of blue tack to hold the brass in position whilst I apply thin CA.

View attachment 121590

This photo shows the first level of all three superstructures in position.

View attachment 121589

This photo shows an error on the kit where the margin rail has been missed out, and I have used some Evergreen to replace it.

View attachment 121588

I found it easier to lose the 1mm deck length error between the forward and mid-section of the superstructure, I had to trim the semi-circular deck sections just forward of the pencil. Bear in mind I am using a wooden deck so it is an easy matter to hide the mismatch.

View attachment 121587

Derek

View attachment 121591

View attachment 121593

View attachment 121594

View attachment 121595

N

noble

Guest

Nice mate......very nice.

Scott

Scott

C

Caledonia

Guest

Thanks Scott, it's always nice to get feed back.

The lower Bridge front panel is of clear plastic in order to allow you to mask the windows for painting. I have chosen to drill and file out the windows, I don’t fancy masking such small windows. After painting the model, I may choose to use glazing solution. Similarly I have omitted the clear plastic Item P5, and may use glazing solution instead.

View attachment 122072

I have added an Evergreen 1mm x 2mm strip and filed it down to eliminate the 1mm deck gap on the superstructure. Also I have attached the mid and aft sections of the superstructure and reinforced the joints. I will eventually attach the forward superstructure section to the mid-section at a later date.

View attachment 122069

Dragon have several unidentified parts, L38 and L40 fits to the sides of L10, also H1 goes under H10.

Have been busy making sub-assemblies; the following photos show the sub-assemblies and a dry fit on each area. I will add the PE to the sub-assemblies next.

View attachment 122064

The sub-assemblies have been chosen with fitting the wooden decks and the order of painting in mind. Derek

View attachment 122065

View attachment 122067

View attachment 122068

View attachment 122071

The lower Bridge front panel is of clear plastic in order to allow you to mask the windows for painting. I have chosen to drill and file out the windows, I don’t fancy masking such small windows. After painting the model, I may choose to use glazing solution. Similarly I have omitted the clear plastic Item P5, and may use glazing solution instead.

View attachment 122072

I have added an Evergreen 1mm x 2mm strip and filed it down to eliminate the 1mm deck gap on the superstructure. Also I have attached the mid and aft sections of the superstructure and reinforced the joints. I will eventually attach the forward superstructure section to the mid-section at a later date.

View attachment 122069

Dragon have several unidentified parts, L38 and L40 fits to the sides of L10, also H1 goes under H10.

Have been busy making sub-assemblies; the following photos show the sub-assemblies and a dry fit on each area. I will add the PE to the sub-assemblies next.

View attachment 122064

The sub-assemblies have been chosen with fitting the wooden decks and the order of painting in mind. Derek

View attachment 122065

View attachment 122067

View attachment 122068

View attachment 122071