B

Bunkerbarge

Guest

I thought I would share a few pictures of the progress of my steam boat with the members of the forum and maybe pass on a few of my own trials, tribulations and ideas.

The first couple of pictures show the very early stages of hull preparation and a few modifications I made to the basic kit. The kit is a Mountfleet models “Ben Ain” North Sea Steam coaster and consists of a fibre glass hull, a set of plans, a collection of strip wood and printed ply panels and a box of white metal fittings. One of the first things was to think of how I wanted the steam plant to work as this has a direct impact on the internal layout. I did want a boiler feed tank so that I could pump up the boiler with feed as it was used so that meant I had to include a feed tank in the construction. As I wanted to balance the weight of the boiler and engine at the aft end and I wanted as much space available as possible I decided to make the feed tank in the bow.

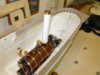

One picture shows test fitting the tank in the bow before putting the top on and inside can be seen the baffles to reduce free surface effect of the feed water. Another convenience of having the tank here is that it can be easily be connected to the accommodation vent cowls for filing and venting the tank, which I did at a later stage. The tank was made of polystyrene sheet which should give suitable water resistance and was easy to work with. Inside the hull can be seen the gloss cram paint finish which serves the purpose of being easy to wipe clean when being used. I used a radiator paint to resist any heat effects of the boiler and put a total of three coats on to smooth out the fibre glass internal finish. Also in the hull shot can be seen the boiler and engine mounting frames and the fist piece of wood to be used as a bearer for the steam plant. After the initial bath trials I estimated that about 30-35 lbs of ballast was going to be needed so I manufactured two steel plates, 16cm x 16 cm x 8mm thick and laid them in the bottom of the hull. This area was dammed with the three wooden bearers and completely encased in resin so that the brass base plate had something to screw to when it came time to fit. Also the inside of the bilge keel can be seen and the tabs used to locate them.

The aim of the effect of the finished boat is that it will look weathered and as realistic as possible from the outside but when it is opened up this will contrast with the insides, which will be the gleaming pristine brass and copper steam plant. That is the theory anyway. To help with this effect the outside of the hull had rivet detail added on the platework. I tried to emulate the correct rivet arrangement as used on real coasters of the time and used thick gel superglue to create the rivets. Riveting the hull took me most of my spare time for a week with regular rests to regain the feeling in my hands.

One last thing of note is the fore deck planking. The kit includes a printed ply overlay, which has all the grain going across all the planks. To improve the effect I planked the deck myself using lime strip wood and finishing off with a mixture of weatherproof PVA glus mixed with black powder paint. The resultant mix was rubbed into all the caulking and saned down to give the overall deck finish. The deck was then coated with three coats of matt yacht varnish and rubbed down between coats.

View attachment 13130

View attachment 13131

View attachment 13132

View attachment 13133

The first couple of pictures show the very early stages of hull preparation and a few modifications I made to the basic kit. The kit is a Mountfleet models “Ben Ain” North Sea Steam coaster and consists of a fibre glass hull, a set of plans, a collection of strip wood and printed ply panels and a box of white metal fittings. One of the first things was to think of how I wanted the steam plant to work as this has a direct impact on the internal layout. I did want a boiler feed tank so that I could pump up the boiler with feed as it was used so that meant I had to include a feed tank in the construction. As I wanted to balance the weight of the boiler and engine at the aft end and I wanted as much space available as possible I decided to make the feed tank in the bow.

One picture shows test fitting the tank in the bow before putting the top on and inside can be seen the baffles to reduce free surface effect of the feed water. Another convenience of having the tank here is that it can be easily be connected to the accommodation vent cowls for filing and venting the tank, which I did at a later stage. The tank was made of polystyrene sheet which should give suitable water resistance and was easy to work with. Inside the hull can be seen the gloss cram paint finish which serves the purpose of being easy to wipe clean when being used. I used a radiator paint to resist any heat effects of the boiler and put a total of three coats on to smooth out the fibre glass internal finish. Also in the hull shot can be seen the boiler and engine mounting frames and the fist piece of wood to be used as a bearer for the steam plant. After the initial bath trials I estimated that about 30-35 lbs of ballast was going to be needed so I manufactured two steel plates, 16cm x 16 cm x 8mm thick and laid them in the bottom of the hull. This area was dammed with the three wooden bearers and completely encased in resin so that the brass base plate had something to screw to when it came time to fit. Also the inside of the bilge keel can be seen and the tabs used to locate them.

The aim of the effect of the finished boat is that it will look weathered and as realistic as possible from the outside but when it is opened up this will contrast with the insides, which will be the gleaming pristine brass and copper steam plant. That is the theory anyway. To help with this effect the outside of the hull had rivet detail added on the platework. I tried to emulate the correct rivet arrangement as used on real coasters of the time and used thick gel superglue to create the rivets. Riveting the hull took me most of my spare time for a week with regular rests to regain the feeling in my hands.

One last thing of note is the fore deck planking. The kit includes a printed ply overlay, which has all the grain going across all the planks. To improve the effect I planked the deck myself using lime strip wood and finishing off with a mixture of weatherproof PVA glus mixed with black powder paint. The resultant mix was rubbed into all the caulking and saned down to give the overall deck finish. The deck was then coated with three coats of matt yacht varnish and rubbed down between coats.

View attachment 13130

View attachment 13131

View attachment 13132

View attachment 13133