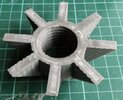

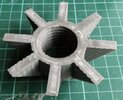

Spool nut printed - it stuck well - I think I've got the bed temperature a little high - the bottom surface has the texture of the new build plate....................

The big question - will the nut fit the thread??

The answer is YES!!! a bit rough at first, but once I'd run it up and down the thread, and taken off the sharp edges

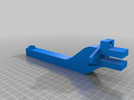

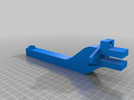

The third & final part is the support arm - this has to be printed diagonally across the build plate, otherwise it won't fit.

This is different to the other parts, it needs supports - temporary props to support the overhangs. The slicing programme automatically adds these - you can do it manually, but having no experience of this, I want to see how the programme does it. The supports can be easily ( ?! ) broken away when the print has finished.

So far all is going well. I've ordered some cork matting to put under the feet of the printer - it's on a cantilever computer desk, with a formica surface, and it does vibrate & jump around a bit. It's not that noisy, but running for long periods ( hours + ), it could be annoying. I can't hear it in my bedroom, with the door closed, so overnight printing is possible, I just have to have confidence it doesn't screw up the minute I close the door. I've also ordered spare belts & a nozzle, as I reckon these are the parts that could give out!

Dave

Dave

The big question - will the nut fit the thread??

The answer is YES!!! a bit rough at first, but once I'd run it up and down the thread, and taken off the sharp edges

The third & final part is the support arm - this has to be printed diagonally across the build plate, otherwise it won't fit.

This is different to the other parts, it needs supports - temporary props to support the overhangs. The slicing programme automatically adds these - you can do it manually, but having no experience of this, I want to see how the programme does it. The supports can be easily ( ?! ) broken away when the print has finished.

So far all is going well. I've ordered some cork matting to put under the feet of the printer - it's on a cantilever computer desk, with a formica surface, and it does vibrate & jump around a bit. It's not that noisy, but running for long periods ( hours + ), it could be annoying. I can't hear it in my bedroom, with the door closed, so overnight printing is possible, I just have to have confidence it doesn't screw up the minute I close the door. I've also ordered spare belts & a nozzle, as I reckon these are the parts that could give out!

Dave

Dave