Modifications and updates to the mittlerer Zugkraftwagen 8T (Sd.Kfz.7) Holzpritsche

As we are yet to start on the bodywork and cargo bed, I thought it may be worthwhile at this point to mention the various modifications that occurred during its short production run. Most changes were features that were dropped due to the materials savings plan.

First up as regards to manufacturers, the HL reference refers to vehicles manufactured under licence by Borgward and KM by Krauss Maffei

The first wooden cargo bodies (Holzpritsche) built on the m11 design were installed by the manufacturer Saurer as early as November 1943. These were first attached to the 1943 Typ HL m11 which retained the old-style metal driver’s compartment. At about the same time the assembly firm emblems were dropped from the radiator housing, as were the turn signals, side light and brake light. The headlights were also reduced in size and a pair of steel pins were welded to the front of the frame either side of the towing point to allow mounting of an external starter. The track guards were also reduced in depth.

Early cab with a reduced depth track guard and large headlights

Dragon released a version in 2014 which they labelled a ‘Typ HL M11 1943 production’ in kit #6794 which had reduced depth track guards on the box art. Unfortunately, the kit only provided existing body floor mouldings with the older type of track guard and expected the modeller to reduce them by slicing them along their full length

This without any template or guide marks!

In 1944 the driver’s compartment was re-designed into the final, larger but simplified wooden cab version with a new instrument panel and angled track guards. The open glass panel in the windscreen was dropped and at least three variations in the design of the wooden side panels of the driver’s compartment existed. These being a rounded front, a second with a short straight bevel and a third with a long bevel. Krauss-Maffei were unable to start there Holtzpritsche production until Feb 1944 of which, by then, they would have likely been with the new cab layout.

Other modifications that are not so visibly obvious included the discontinuation of the inertia starter in 1944, The guide to access this and the cover plate were eliminated from the right front mudguard in early 1944. The final lightweight track plates were also introduced later that year.

The only changes to the cargo body were that the rifle racks were mounted to the equipment rack rather than to the floor. This meant that the Holzpritsche could be converted to a flatbed cargo vehicle simply by removing the seats and equipment rack.

Factory fresh. This has the large headlights, rounded cab panel profile and steel pins for an external starter. There is no assembly firm emblem visible on the radiator housing.

As for the issues and errors with this kit, there are many, but thankfully nothing that spoils it sufficiently to require a huge amount of extra work. Dimensionally the kit is a smidgen long compared to the drawings and the profile of the front fenders is slightly out. Neither warrants the amount of work required to correct IMO.

The kit only provides the larger headlights and has the access cover plate for the inertia starter on the right front mudguard. Both are easy to deal with if you wish to show a later build. Kubelwagen sized headlights being a good replacement. The kit does not provide the steel pins for the external starter either side of the front towing point so you might wish to add these. There is no driver's sun visor on the windscreen in the box either!

As already mentioned in step 16, the cab seat bench metalwork, and the seat cushion size and layout are incorrect. If it is important to you, these will need to be modified. The assembly firm emblem on the radiator housing is easy enough to remove should you wish and the three prominent rivets at the bottom of each fender should not have a bolt head on each. These look like a restoration anomaly so simply remove the bolt detail.

As for the cargo bed, there are a few errors and omissions here too. The PT drawings and period images show a cut out at the top of the rear tailgate. This was to accommodate items being towed and the kit part does not include this. It doesn't provide the steps on the interior of the same part either! Both these should be easy enough to correct. Later models had the rifle racks located onto the equipment rack. Trumpeter have a strange photo etch frame (part) PE-WB15 attached to the top clasps which are not shown in either PT drawings or period images. Maybe best to leave these off? The lower rifle butt locating rings are moulded to the floor on the kit. Later variants moved these to the equipment rack. As far as I can make out, they look to have been re-located to the top of the bottom plank.

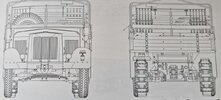

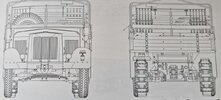

No assembly firm emblem, pins for the external starter, small headlights, windscreen sun visor, and the tailgate cut out and steps can all be seen in these drawings. It also shows the lightweight track design introduced at the end of 1944.

The equipment rack was attached the cargo floor by locating bars which fitted into sockets in the floor. They were, as the seat was, locked in place by blocks attached to the inside of the folding sides. The kit does not provide either of these. The bars would not be visible if fitted but the blocks would be. Again, a simple process to scratch from plastic card. Likewise, the sockets in the floor are not shown on the kit part and would be visible if you built a flatbed cargo version.

Strangely the cargo seats provided are engineered to sit opposite each other where in fact it sat across the width of the whole bed with seats facing back-to-back. There are also twin planked wooden seat back looking frames attached to each folding side. I’m pretty sure this is where Trumpeter researchers misinterpreted these as the seats and include a two benches positioned each side. Who knows?

The actual bench sits accross the bed (inside the red rectangle)

Lastly, the kit's instructions have you place the spare wheel (without any means of securing it) on the flat panel at the rear of the chassis when it should sit in the tools compartment in front of the equipment rack.

Scale drawings of both the equipment rack and cargo seat layout can be found in Panzer Tracts No 22-4 if you wish to scratch build them.

The Crompton collection 8T. You can see the rear bench seat layout clearly in these pics

Nice pic of the cab instrument panel layout

What a numptie

What a numptie

This without any template or guide marks!

This without any template or guide marks!